Whatever your industry, we can assist you in protecting worker health and safety, safeguard sensitive equipment and protect your surrounding environment. HGC Engineering has designed specified, and supervised successful installations of effective industrial noise and vibration control measures for Canadian, American and Global industrial market leaders around the world.

The Cost Benefits of Predictive Noise and Vibration Studies

For virtually every industrial project, incorporating noise and vibration control into the early stages of design is more effective and cheaper than fixing a noise problem later. Doing so often requires a predictive approach, in order to predict, analyze and assess future levels of noise and vibration from equipment that has not yet been commissioned.

Acoustical Engineering Expertise with Industrial Application Challenges

Over the past two decades, HGC Engineering has undertaken hundreds of predictive studies – from 1000 MW power plants to oil refineries to large scale food production plants – to determine accurately and in advance what sound and vibration will be produced by process equipment, heating, ventilation & air conditioning (HVAC) systems, as well as shipping and receiving activities.

A Team Approach to Solving Noise & Vibration Control Problems

Where the anticipated sound or vibration levels exceed the design targets, we use our analytical expertise to rank the sources, identify those requiring control measures, and develop a range of options to allow the design team to select the best solution. Our approach has always been to work closely with the manufacturers, suppliers and installers of noise and vibration control products, like silencers, mufflers, acoustical enclosures, spring isolators and elastomeric pads, to stay on the leading edge of the control technologies that are available and the physics that make them work. In fact, many manufacturers of noise and vibration control products hire us to help them develop newer, more effective technologies, and prototype test their performance.

Wafer Fab Parks, Singapore

Etileno XXI Petrochemical Complex, Mexico

Anheuser-Busch Brewery & Distribution Facility, Columbus, Ohio

Interior Workplace Noise Control Methods Demystified

What is Sound Intensity Measurement and Analysis?

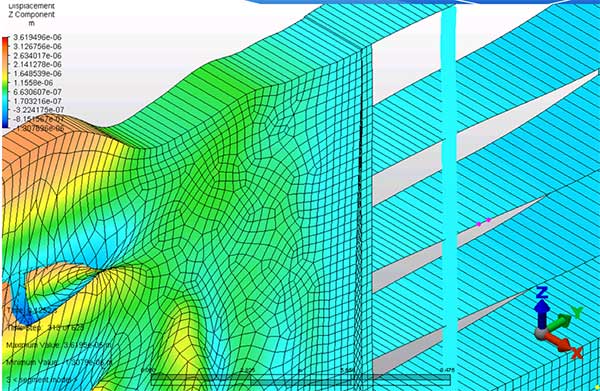

What is Vibration Modal and Fatigue Analysis?

NPC-300 brings major changes to Ontario’s environmental noise guidelines

Need Answers?

Reach out to our acoustical consultants now.