What is Sound Intensity Measurement and Analysis?

Sound intensity describes the flow of acoustic energy produced by a sound source. Unlike simple microphones and sound level meters, sound intensity measurements accurately capture only the sound produced by the source under test, eliminating interference from other sounds. HGC Engineering provides sound intensity measurement to a wide range of industries from high-tech product manufacturers to power generation.

The state of the art is the measurement of sound intensity

Sound intensity measurement makes it possible to achieve on-site, highly accurate, time-efficient measurements in noisy locations and allows for a more effective design of noise control or improved acoustics.

HGC Engineering uses sound intensity measurement methods to:

- Accurately determine sound power ratings for equipment and products, eliminating the need for expensive acoustical laboratories or anechoic chambers

- Reduce prototype and research and development costs for complex industrial equipment and vehicle noise issues

- Isolate and rank individual sources in a complicated soundfield

- Provide research and development assistance for improved noise control and enhanced sound quality

HGC has pioneered the use of these methods in new applications including gas turbine exhaust stacks, development of novel acoustical building materials, and measurement of sound absorption. Our client base includes work for companies ranging from TransCanada Pipelines to Xerox to General Motors.

How Does Sound Intensity Work?

When acoustic energy flows through air, one result is a fluctuation of air pressure. A microphone measures sound in terms of these pressure fluctuations. However, sound pressure is only part of the whole picture. ]In some situations there is plenty of sound pressure, but little or no overall flow of acoustical energy. A sound field includes both acoustic pressure and particle velocity. Sound intensity is the product of sound pressure and acoustic particle velocity. It is measured in units of Watts per square metre or decibels relative to one picoWatt per square metre.

Acoustical particle velocity is difficult to measure. The most common method of measuring the particle velocity is a pair of phase-matched microphones locked at a fixed distance apart. By comparing the differences between the sound signal at the two microphones, the sound intensity analyzer can compute both the sound pressure and particle velocity at the mid-point between the two microphones, and can multiply the two together to compute the sound intensity. Because sound intensity is based on both acoustic pressure and velocity it has a direction. A two-microphone sound intensity probe measures only the component of the total sound intensity traveling parallel to the axis of the probe. As shown in the above illustrations, a sound originating in front of the probe will be measured as a positive intensity, whereas a sound from behind the probe will be negative.

Immunity to Background Sound

A sound intensity probe measures only the component of the sound traveling parallel to the probe axis. Sound traveling toward the probe is measured as positive intensity, while sound traveling opposite to the direction of the probe registers as negative intensity.

When measurements are made with the probe over an imaginary surface enclosing the source under test, background sounds pass into one side of the enclosing surface and back out the opposite side. In this way, the background sounds cancel out and the measurement includes only the sound originating inside the measurement surface. Room effects such as reverberation are eliminated in the same way.

Improved Accuracy

Measurement quality is improved by the inherent immunity to background sound and to reverberation available through sound intensity methods. Precision Grade or Engineering Grade measurements, in full accordance with ISO and ANSI standards can be conducted in virtually any location indoors or outdoors

On-site Measurements

In the past, accurate sound power ratings of equipment required that the device be shipped to an acoustical laboratory chamber. Sound intensity methods offer the option of gathering highly accurate measurements at your facility, in-situ, with little disruption to processes or activities. On-site measurements offer time and cost savings and can accommodate iterative testing for product research and development applications.

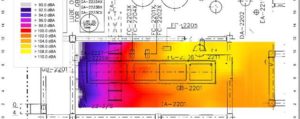

Identification, Isolation and Ranking Individual Sound Sources

In reducing worker noise exposures inside an industrial plant, or environmental noise emissions outdoors, sound intensity measurement allows accurate identification, isolation and ranking of individual sound sources. In this way, informed decisions can be made about how much noise control each piece of equipment may require. For complex machines and processes, the noisy components can be identified and treated.