STC vs ASTC Ratings in the Amended Ontario Building Code Explained

Changes to the Ontario Building Code with regards to airborne sound insulation requirements

A common request that we encounter as acoustical consultants is to evaluate a building partition’s ability to limit airborne noise transmission, and to evaluate that performance against the project requirements. Often, these requirements are those stated in the relevant building code, though at times higher targets may be warranted (e.g., to separate a noisy space from a noise-sensitive space, or simply where enhanced sound insulation is desired).

On January 1, 2020, amendments to the Ontario Building Code (OBC) pertaining to the required airborne sound insulation between residential dwelling units came into effect. This post will discuss the old building code as well as the new code, how to interpret the changes, and what that means for the design and construction of demising assemblies which must meet these requirements.

The previous version of the building code states that every dwelling unit shall be separated from every other “noise-generating space” in a building by an assembly providing a sound transmission class rating (or STC rating) of at least 50. The code further stated that where dwelling units are adjacent to elevator shafts and garbage chutes, the separating assembly shall have an STC rating of at least 55.

In some cases the OBC now considers the ASTC rating rather than simply the STC rating

The new version of the OBC considers both the Apparent Sound Transmission Class (ASTC) rating and STC rating, and in some cases, the applicable code requirement is now a minimum ASTC rating instead of a minimum STC rating. The STC rating and the ASTC rating are related, but are not the same; the STC rating of an assembly corresponds to the airborne sound insulation performance of an assembly tested in a laboratory setting, whereas the ASTC rating of that same assembly corresponds to an in-situ or field test.

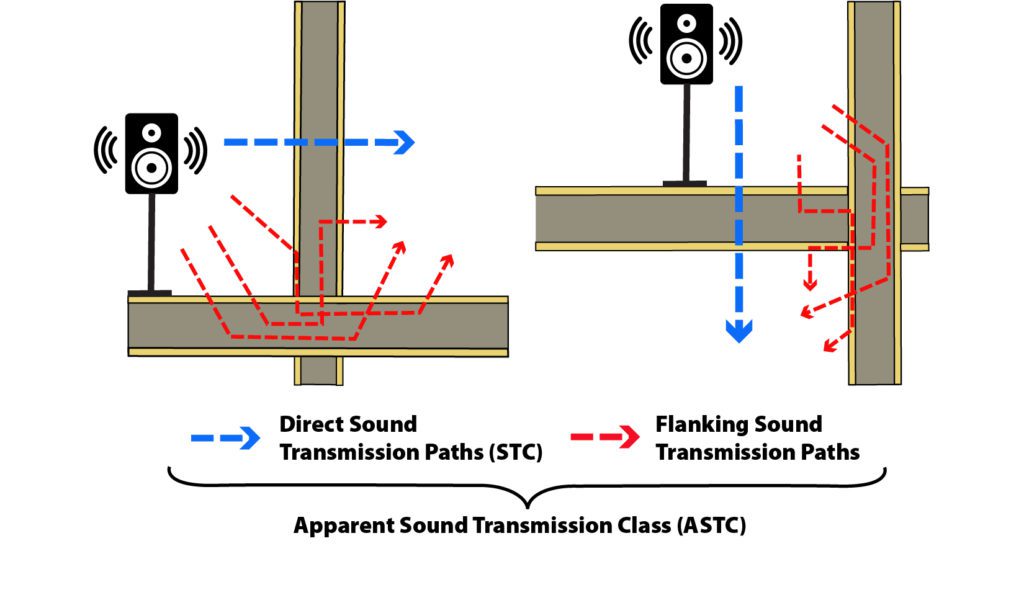

Laboratory tests rooms are carefully designed and constructed such that an STC test measures only the transmission of sound directly through the demising assembly under test (e.g., only directly through the wall or floor/ceiling). In a field or in-situ test, the contribution of both transmission directly through the assembly and transmission by other indirect paths (known generally as flanking paths) affects the overall result. These flanking paths can include transmission around the demising assembly, such as through common floors, ceilings, or walls which may be adjacent to the assembly under test. Other factors can lead to degradation in field test performance as well (e.g., construction deficiencies such as poorly applied sealant, leakage through back-to-back electrical or communication boxes). Because these flanking paths are always present to some degree in a field test, the ASTC rating of an assembly will always be equal to or less than the STC rating of the same assembly.

The updated version of the Ontario Building Code provides two options to demonstrate compliance of an assembly:

- The first way is to demonstrate that the assembly and adjoining construction collectively meet an ASTC rating of 47 or greater; the ASTC rating can be measured in the field to demonstrate compliance (often a random, representative sampling is selected, or in some instances, a test of a specific instance of a partition/condition is desired), or, in some cases, the ASTC rating can be determined theoretically through calculation, which requires details of not only the assembly itself, but also knowledge of the adjacent assemblies (i.e., floors, ceilings, and walls perpendicular to the assembly), as well as details indicating how junctions are constructed.

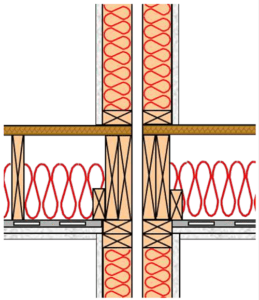

- The second way a partition can demonstrate compliance is to select an assembly which meets a minimum laboratory rating of STC-50, in conjunction with strict requirements on the adjoining construction (floors, ceilings, etc.), and the details of their junctions, which are listed in the OBC.

The implications of the modifications to the code can be significant, and each of the methods to demonstrate compliance has its own advantages and disadvantages.

Conducting field tests to determine compliance with ASTC requirements

-

Insufficient caulking can cause noise transmission issues In the event that the assembly and adjoining constructions have already been designed and/or constructed, a field test can be conducted to determine if the ASTC rating is in compliance with the building code. While this field test is generally much simpler and quicker than calculating the ASTC rating, this approach risks a poorly designed and constructed demising assembly resulting in non-compliance with respect to the OBC requirements. Excessive sound transmission directly through the demising assembly or through various potential flanking paths can result in an unfavourable test result (i.e., less than the code requirement of ASTC-47 or less than the expected performance of the demising assembly). In this case, an acoustical consultant may be able to recommend corrective measures or analysis of the test results; this may range from application of additional sealant to removal and replacement of components of the partition itself. It can be complex and costly to address the deficiency, particularly when many such instances of the separating assembly have already been constructed.

Using calculations to determine compliance with ASTC requirements

- Where calculations are used to determine compliance with the required ASTC ratings during the design phase, additional input is required to ensure that the junctions are appropriately detailed (and subsequently constructed). This method can be advantageous in that code compliance is achieved during the design stage and a field test is not necessarily required to demonstrate compliance with the code, avoiding the potential for undesirable re-work during construction; however, this method can be much more complex than a field test, and thus can require more time to complete.

Using laboratory test data to determine compliance with STC requirements

- The last method of demonstrating compliance involves using the laboratory STC rating in conjunction with very specific adjoining constructions (as detailed in the code). This can be a simple and effective method to demonstrate code compliance during the design phase, particularly in buildings which use heavy cast-in-place or masonry structures, where the requirements on the adjoining constructions are relatively simple. For lightweight or wood-framed assemblies, very specific requirements on the adjoining constructions are detailed in the OBC, and deviations from these requirements do not allow for using the STC rating to certify compliance (i.e., an ASTC rating is required).

When designing a building where these requirements apply, an acoustical consultant can help determine which method(s) of demonstrating compliance with the building code may be best for a given project, and can provide support throughout both design and construction to ensure compliance with the building code or other project target is achieved. In general, having an acoustical consultant review the proposed demising assemblies early in the design phase of the project is the best way to ensure that building code or other project requirements are met without incurring additional effort, costs, or delays.