Northeast Vaughan Wastewater Servicing Project

Location: Vaughan, Ontario, Canada

Owner/Operator: The Regional Municipality of York

Design Engineering: Jacobs

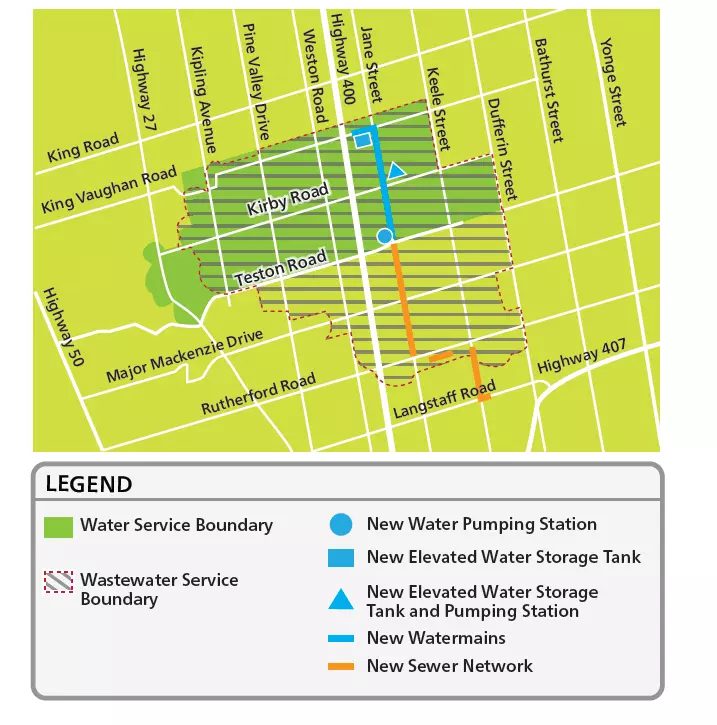

The northeast portion of the City of Vaughan (City) in the Regional Municipality of York (York Region) is anticipated to experience significant population growth in the coming decades. However, the existing water and wastewater systems are unable to accommodate the projected population growth. The Northeast Vaughan Wastewater Servicing project includes the construction of a new trunk sewer from the intersection of Jane Street and Teston Road to the vicinity of the junction of Keele Street and Langstaff Road. The trunk sewer will provide sufficient capacity to service the projected growth in Northeast Vaughan to the year 2051 and will also include a parallel relief sewer between Jane Street and Keele Street along the route of the existing Jane-Rutherford trunk sewer. The sewer will be approximately 11 kilometres long with a 3 metre internal diameter. A tunnel contractor has been contracted to supply two TBMs to execute the 3 metre tunnel (internal diameter) and the 250 millimetre thickness precast concrete segments (PCTL) necessary for tunnel lining. The overall capital cost of the tunnel (phase one) trunk sewer has been estimated at approximately $315 million. The anticipated completion date is expected to be 2028.

Noise and Vibration Study Work Plan and Study

HGC was brought into this project as part of the design team. We initially prepared a Noise and Vibration Study Work Plan document, detailing the proposed steps required in preparation of a Noise and Vibration Study. These steps included a detailed review of drawings, discussions with project personnel about proposed construction sequencing and activities, a tour of the areas, a review of applicable provincial and municipal guidelines and criteria, preparation of a predictive noise and vibration model of the area, a systematic assessment of anticipated noise and vibration impacts, the generation of figures, summary tables, etc., and preparation of draft and final versions of the study report.

As they became available, HGC reviewed the latest drawings and satellite imaging for the areas nearest to the work areas. We then discussed, with appropriate project personnel, the proposed construction activities, including details of the construction of the elevated water tanks, any proposed pipe-jack TMB(s) and associated spoil-removal systems, excavations and shoring procedures and equipment for the construction of vertical shafts, proposed procedures and equipment for cut-and-cover work, etc. We also considered likely construction timelines, schedules, and hours of operation.

HGC toured the areas through, or under which work would proceed, concentrating on areas where access shafts or drop shafts would be constructed, or cut and cover work would be performed.

Baseline Noise and Vibration Levels

A series of representative receptor locations were then identified representing the major work areas. They were elected by considering the likely degree of noise or vibration impact, the distance from work areas or the depth of the tunnel, the proximity to existing noise or vibration sources, etc. Baseline noise and vibration levels were then measured established for the project.

Attended Noise and Vibration Measurements

Short-term attended noise and vibration measurements were conducted near each of the selected representative receiver locations. Where night-time work was likely expected in some areas, night-time measurement were conducted near the sensitive receiver(s) closest to such areas.

Construction Noise and Vibration Criteria

A summary of relevant criteria addressing construction noise and vibration was then prepared, including limits discussed in Vaughan’s By-laws, guidelines of the Ministry of Environment Conservation and Parks, and criteria commonly used in other jurisdictions.

Acoustical Model of Construction Work

An acoustical model of at-grade construction work was prepared using manufacturer’s sound level data for major equipment items (where available), generic sound level data from our files, or generic data from published references. Figures presenting contours of anticipated sound levels due to construction were also prepared.

Vibration Zones of Influence

Predictions of construction vibration were made, taking into account the anticipated construction equipment, the depth of the work, etc. and based on published reference data and data from our files. Figures illustrating the predicted vibration Zones of Influence were also prepared.

Noise and Vibration Management Plan

A Construction Noise and Vibration Management Plan was also prepared. This plan articulates the responsibility for various noise and vibration management efforts, establishes various prohibitions and requirements to control noise and vibration, and describes various good-practice noise and vibration mitigation techniques and potential additional mitigation measures that could be implemented in the event of excessive noise or vibration impacts. Requirements for noise and vibration measurements, monitoring, and reporting are established for the future construction.

Hospital-related Vibration Considerations

As project work on a later phase of the project will be conducted relatively close to the Cortellucci Vaughan Hospital, we plan to meet with hospital staff to identify equipment installed in the facility which may be sensitive to vibration. We also plan to conduct background vibration measurements at the location(s) of relevant equipment. In many cases, Healthcare facilities make use of equipment such as MRI scanners which are sensitive to vibration at levels well below typical construction vibration criteria intended to safeguard buildings and structures.

Acoustical Consulting Service Being Delivered:

- Establishing Baseline Noise and Vibration Levels

- Acoustical modelling of surface work areas

- Predicting Vibration Zones of Influence

- Construction Noise & Vibration Management Reporting

- Noise and Vibration Monitoring Program