Fairbank Silverthorn Storm Trunk Sewer System

Location: Toronto, Ontario, Canada

Project Owner: City of Toronto

Design Engineering: Jacobs

The roots of this massive $400-million infrastructure project go back to August 2005 when a major storm dropped approximately 130 millimeters of rain on Toronto, causing flooding in many residents’ homes, erosion in city ravines and watercourses, and damage to area roads, bridges, culverts, and roads.

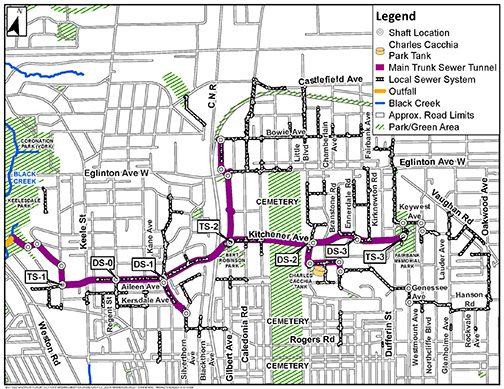

As a part of the City of Toronto’s Basement Flooding Protection Program the goal of this tunneling project is to protect more than 4,600 homes and businesses in a 140-hectare area of northwest Toronto from basement flooding. The project involves the building of a new storm sewer system in the Fairbank and Silverthorn neighbourhoods. Fairbank is in the area of Dufferin Street and Eglinton Avenue West, while Silverthorn is in the area of Black Creek Drive and Eglinton Avenue West.

The main tunnel will be created using a tunnel boring machine that typically excavates eight to 10 metres per day. Crews will construct a three-kilometre long, 4.5 metre-diameter storm sewer.

When the project is completed in 2026, the amount of storm water flowing into Black Creek on the western edge of the community will be cut by approximately 40,000 cubic metres,

Noise and Vibration Study Work Plan and Study

HGC Engineering has been involved with this project, as part of the design team, since 2019. We initially reviewed project design drawings and satellite imaging for the areas nearest to the work. We reviewed the proposed construction activities, likely construction timelines, schedules, and hours of operation.

HGC then conducted a tour of the project areas through, or under which work was expected to proceed. A series of representative receptor locations were then identified representing the major work areas. These were selected by considering the likely degree of noise or vibration impact, the distance from work areas or the depth of the tunnel, the proximity to existing noise or vibration sources, etc.

Establishing Baseline Noise and Vibration Levels

Baseline noise and vibration levels were then established for the project. Short-term attended noise and vibration measurement were conducted near each of the selected representative receiver locations. Where night-time work was likely, night-time measurements were also to be conducted near the sensitive receiver(s) closest to such areas.

Acoustical modelling of construction work areas

An acoustical model of at-grade construction was then developed, using manufacturer’s sound level data for major equipment items, generic sound level data from our files, or generic data from published references. Figures presenting contours of anticipated sound levels due to construction were also prepared.

Predicting Vibration Zones of Influence

Construction vibration predictions were made, taking into account the anticipated construction equipment, the depth of the work, etc. and based on published reference data and data from our files. Predicted vibration Zones of Influence were identified.

Construction Noise & Vibration Management Reporting

Reports were then prepared, presenting the baseline noise and vibration data, the modeling results, and summarizing appropriate criteria for environmental noise and ground-borne vibration. The reports also described good-practice noise and vibration mitigation techniques and potential additional mitigation measures that could be implemented in the event of excessive noise or vibration impacts.

Noise and Vibration Monitoring Program

Specifications for a noise and vibration monitoring program were then developed for the project. This included requirements for automated noise and vibration monitoring, and for attended measurements at the start of major activities. Separate specification documents were prepared for each of the two construction tenders, specifying noise and vibration monitoring and mitigation plans.

Once construction began, we began reviewing the contractor’s noise and vibration data and monthly reports, and working regularly with the contractor and design team to keep aware of the noise and vibration monitoring efforts, to review any upcoming plans for monitor installation or relocation, calibration status, etc., and to review mitigation measures or other controls.

HGC also visits the site as needed to inspect the noise and vibration monitoring equipment, mitigation, or other controls, and, if warranted, to conduct attended noise and vibration verification measurements during construction activities,

Acoustical Consulting Service Being Delivered:

- Noise and Vibration Study Work Plan and Study

- Establishing Baseline Noise and Vibration Levels

- Acoustical modelling of surface work areas

- Predicting Vibration Zones of Influence

- Construction Noise & Vibration Management Reporting

- Noise and Vibration Monitoring Program