The Coxwell Bypass Tunnel Project

Location: Toronto, Ontario, Canada

Owner/ Operator: City of Toronto

Project Consortium Team: North Tunnel Constructors (JayDee Canada, Michels Canada, and C&M McNally Tunnel Constructors)

Engineering Design: Black & Veatch, R.V. Anderson

Operator: Toronto Transit Commission (TTC)

The City of Toronto has embarked on the largest and most significant stormwater management program in the city’s history. The Coxwell Bypass Tunnel project is the first of a five-phase 25-year, $3-billion infrastructure initiative in the city of Toronto’s Wet Weather Flow Master Plan that will eliminate the release of combined sewer overflows and polluted water to the Don River and Lake Ontario, while offering key infrastructure upgrades at a new high-rate treatment facility at Toronto’s Ashbridges Bay Treatment Plant, that when completed, is expected significantly improve system capacity.

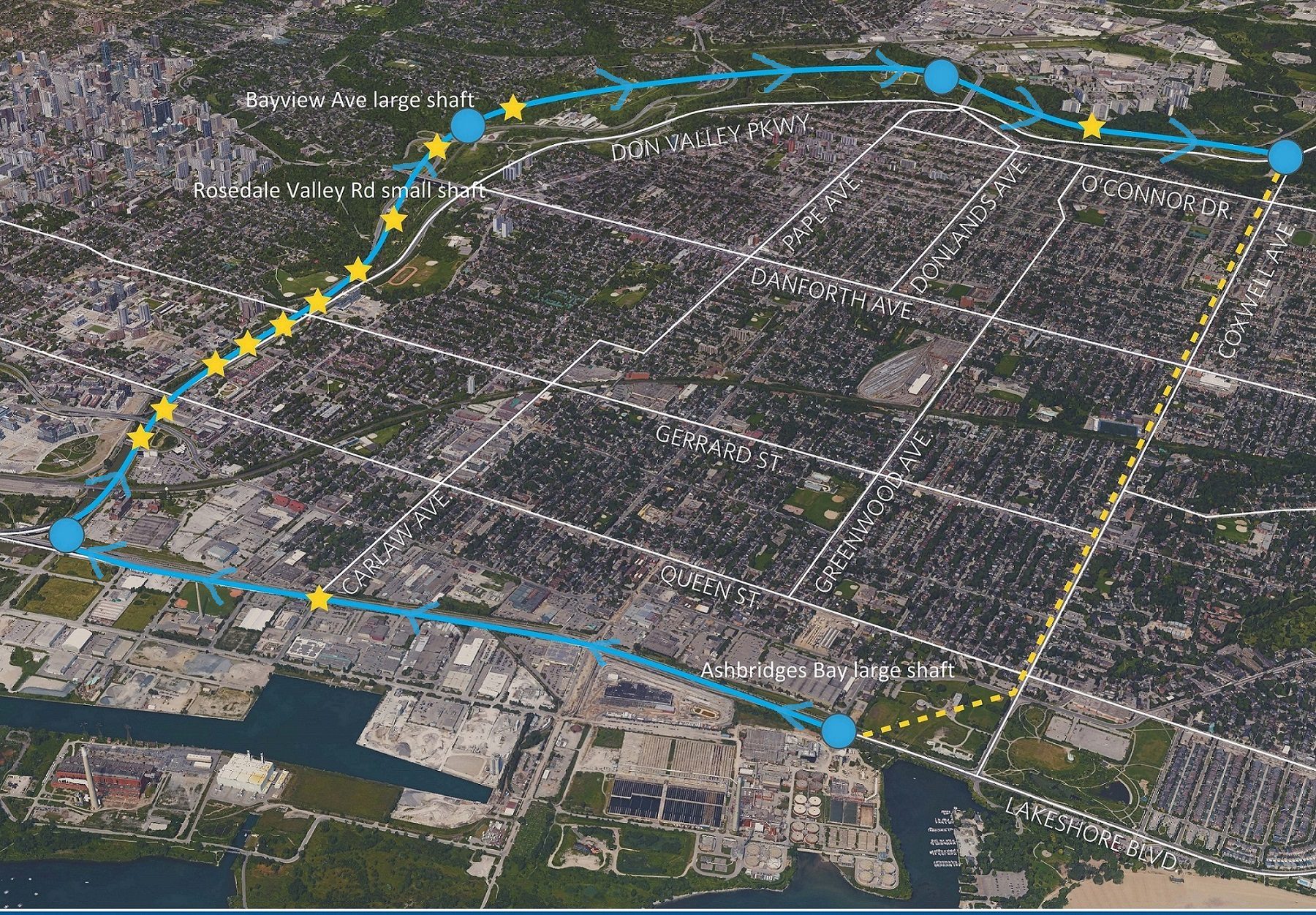

The Coxwell Bypass Tunnel project consists of a 6.3 diameter, 10.5km long tunnel, 5 major work shafts with diameters varying from 20 to 22m at average depths of 50m, and 11 adit tunnels scattered throughout the main tunnel varying in diameter from 3.0m to 8.45m.

In July of 2023, a Tunnel Boring Machine (TBM) nicknamed Donnie successfully completed its 10,339 m tunnel excavation journey. Construction on the Coxwell tunnel began in 2018 and is expected to be completed in early 2024.

The larger Don River & Central Waterfront project includes a 22km-long, three tunnel system, 12 wet weather flow storage shafts along the tunnels, 27 connection points to the tunnels for stormwater and combined sewer overflow, seven off-line storage tanks, and real-time control to regulate flows in the City’s sewer system.

Construction Vibration Study

HGC Engineering was initially retained by the design team to prepare preliminary construction vibration studies required by City of Toronto By-law number 514-2008 for the various TBM launch and access shafts, then for the twelve Wet Weather Flow connection shafts which will each connect one or more existing sewers to the Coxwell Bypass Tunnel, and then finally for the Integrated Pumping Station (IPS) project at Ashbridges Bay Wastewater Treatment Plant.

The studies each involved the prediction of construction-related vibration for each shaft construction project, as well as for tunneling. In cases where there were nearby offsite buildings, a vibration monitoring plan was developed.

Construction Vibration Monitoring

Subsequently we were retained to provide vibration monitoring services during construction associated with the Coxwell Bypass system. This monitoring included vibration monitoring in nearby residential and commercial buildings, above natural gas transmission infrastructure owned by Enbridge (a Canadian pipeline and energy company that owns and operates pipelines throughout Canada and the United States), and on sensitive infrastructure such as major utilities being daylighted during excavation. Monitoring occurred during tunneling, during compaction and vibratory driving of materials, and during shoring and excavation processes.

Film Production Studio Noise and Vibration Impact

One interesting assignment we were asked to undertake related to the project was to assess the potential for project construction noise or vibration to adversely affect filming operations at the Cinespace Booth Avenue film production studios. Cinespace is Ontario’s largest provider of production facilities with over 1.4 million square feet, 29 active stages and production office/support spaces spanning three major campuses, Cinespace Toronto is home to a vibrant content production community, award-winning films and a Netflix production hub.

Normally for an infrastructure project such as this, the focus of concern is predominantly with groundborne vibration capable of causing cosmetic damage to structures. However, the potential concerns at Cinespace and at other nearby recording and film production facilites, related to much lower levels of vibration: the perception of noise and vibration by people working at the studio, and the associated potential for interruptions to the filming or recording process.

At this time The Coxwell Bypass Tunnel is now well into construction, and HGC continues to provide ongoing vibration and noise monitoring campaigns and reporting updates as needed.

Acoustical Consulting Service Being Delivered:

- Identification of Noise and Vibration Sensitive Receptors

- Prediction and Assessment of Noise and Vibration during Construction

- Noise and Vibration Management Planning and Reporting

- Ongoing noise and vibration monitoring