Boundary Element Analysis (BEM) for Acoustical Modeling and Noise Control Design

HGC Engineering has upgraded to the VNoise suite of software as a tool for acoustical modeling of complex systems, such as mufflers, absorptive silencers, resonators, expansion chambers and acoustic plenums. The VNoise software package is based on the boundary element method (BEM), a computational technique which allows fast, efficient analysis for acoustical research and design of noise control devices. Similar to finite element methods (FEM), a model is created by dividing the acoustic system into a mesh of tiny elements, which can be analyzed numerically. However, while FEM requires that the entire acoustic domain of interest be analyzed, BEM only considers the boundary of the acoustic domain, making it an ideal tool to assess automotive noise in passenger cabins or exhaust systems, and industrial noise in piping and ducting systems.

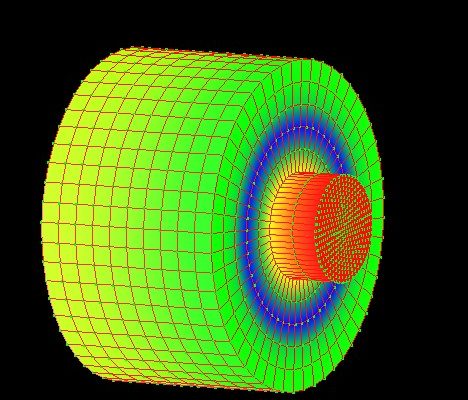

HGC Engineering used VNoise software to design, model and optimize a large-scale acoustic expansion chamber to control low-frequency noise from a mine shaft ventilation fan in West Virginia. The fan was producing a strong tone at 15 Hz, which was shaking and rattling homes at a distance of more than 600 feet. Using the BEM analysis capabilities of VNoise, HGC Engineering tuned the chamber (approximately a 30 foot cube, see graphic ) to provide maximum noise reduction at 15 Hz. Following the computer optimization, a one-tenth scale model was constructed and tested by HGC Engineering to verify the design.