Davenport Diamond Rail Grade Separation Project

Location: Toronto, Ontario, Canada

Project Engineers: EXP, Graham, LEA Consulting, International Bridge Technologies

Architects: Brown & Storey Architects

Owner/Operator: Metrolinx

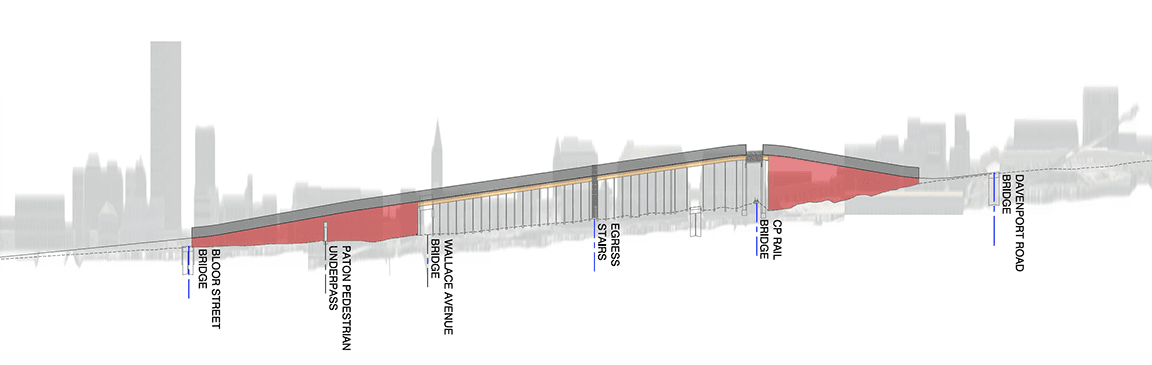

In the Junction Triangle neighbourhood of Toronto, national Canadian Pacific freight trains and local Metrolinx GO trains are at a crossroads, both figuratively and literally. The north-south Barrie Go line, which connects Union Station in Toronto to Allandale Waterfront Station in Barrie, and CP’s east-west freight line meet at a relatively rare at-grade rail crossing near the intersection of Symmington Avenue and Davenport Road known as the Davenport Diamond. The number of GO trains on the Toronto-Barrie line is currently limited in part by the east-west freight traffic on the CP line.

A solution is coming in the form of the Davenport Diamond Rail Grade Separation project. The project involves raising a 2 km stretch of the GO Barrie rail line over the east-west freight line. The $175 million project was awarded to Graham Commuter Rail Solutions in July 2019 and has an expected completion date of Summer 2023.

HGC was retained to complete the difficult task of predicting, assessing and measuring the noise and vibration impacts on neighboring homes and businesses during the three phases of the project: construction, trains operating on a temporary diversion track, and trains operating on the new elevated rail line.

Predicting the Vibration Impact of Elevating a Rail Line

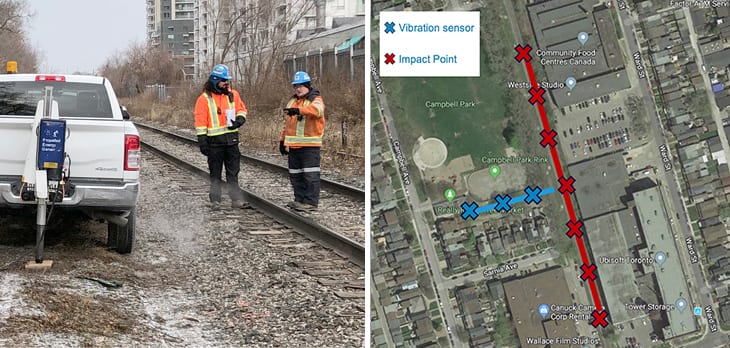

As part of our scope of work, HGC employed a sophisticated vibration modelling technique described by the United States Federal Transit Authority (FTA) in the FTA Transit Noise and Vibration Impact Assessment Manual. A vehicle-mounted impact system was used to repeatedly strike the ground surface, inducing ground-borne vibration at several points along the right-of-way. Analysis of the force input signal and the resulting vibration at a variety of points located at varying distances from the impact was used to portray the vibration propagation characteristics in the area. This type of testing is known as transfer mobility testing. Accurately predicting vibration propagation based on geotechnical explorations can be challenging. One of the great advantages of the transfer mobility technique is that it allows for a much more direct measurement of vibration propagation effects. By repeating the propagation testing near both an existing and a proposed railway, vibration data obtained at one site can be transformed into predictions for an entirely different region.

In the case of the Davenport Diamond site, once the propagation characteristics were known, further analysis was undertaken to model the change in vibration level at nearby sensitive receptors anticipated to be caused by the relocation the railway.

Acoustical consulting service delivered:

- Transfer Mobility Testing (Vibration Propagation Testing)

- Rail Noise and Vibration Prediction using US FTA Transit Noise and Vibration Impact Manual

- Dynamic Finite Element Analysis

- Ground-Borne Vibration Analysis

- Railway Noise Mitigation

- Railway Vibration Measurements and Monitoring