Sound Transmission Issues Caused by Poorly Laminated Drywall on Concrete Partitions

Sound transmission issues are a common source of noise complaints for condo boards, property managers, and developers alike. Speech or singing, amplified music, dogs barking, guitar playing, etc., are all examples of noise sources that may contribute to excessive airborne sound transmission. Many building codes or other regulatory documents require a minimum airborne sound insulation of a partition demising two residential suites, or a residential suite and other noisy areas in a building. This minimum value is typically expressed in terms of the Sound Transmission Class (STC) rating of the assembly; note that the STC rating does not consider the structure-borne sound (e.g., noise from footsteps, furniture moving, items falling on the floor) insulation of an assembly.

Many multifamily residential buildings are constructed out of poured reinforced concrete, and a concrete wall often forms the partition demising residential suites from other suites, the corridor, or other noisy spaces. The sound insulation performance of cast-in-place concrete and other masonry partitions is consistent and well-documented, both in laboratory and field tests.

Challenges of Lamination

A common method of finishing concrete walls in suites is by laminating a layer of drywall directly to the wall using an adhesive. During field tests of such assemblies, it has been observed that the quality of this lamination can have a significant impact on the STC rating of the partition.

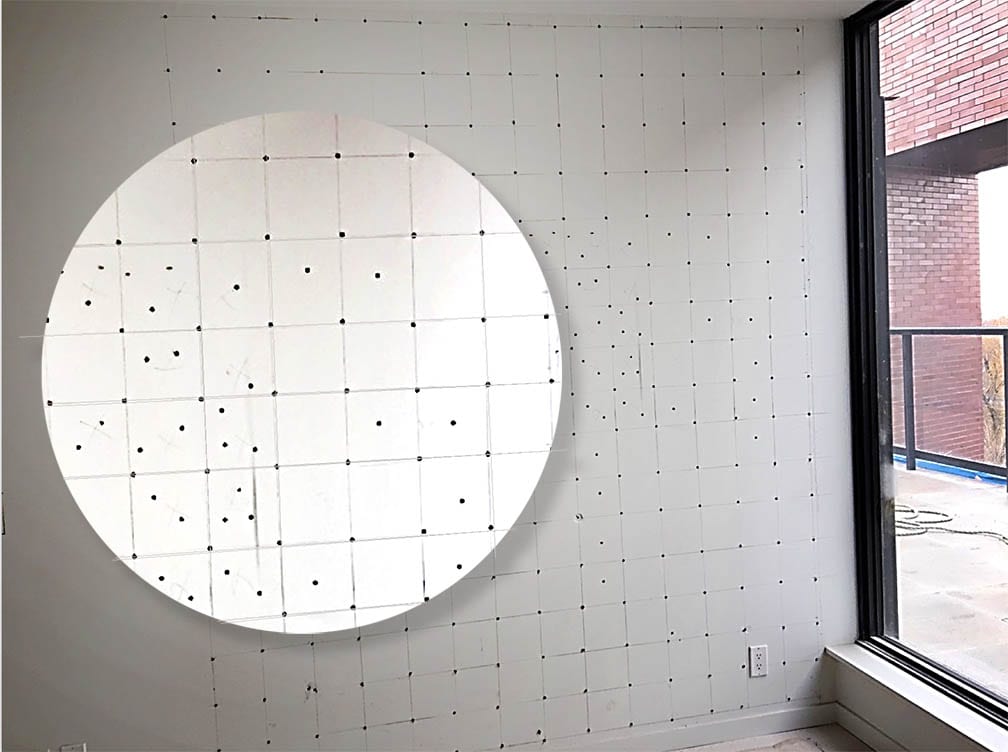

In the field, the approximate spacing between beads of adhesive can be observed by tapping on the wall in a grid pattern and listening; tapping on adhesive beads will have a distinct sound (damped) compared to tapping between beads (hollow). A standard providing directions for application of gypsum board with adhesives to interior masonry or concrete walls (ASTM C-840) defines a measure of application of adhesives as follows:

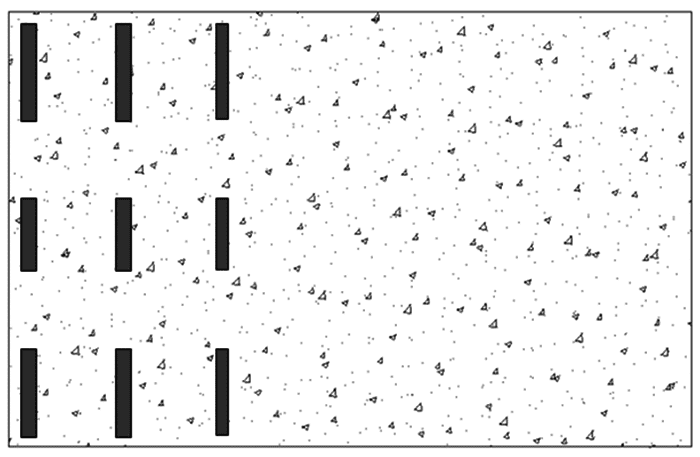

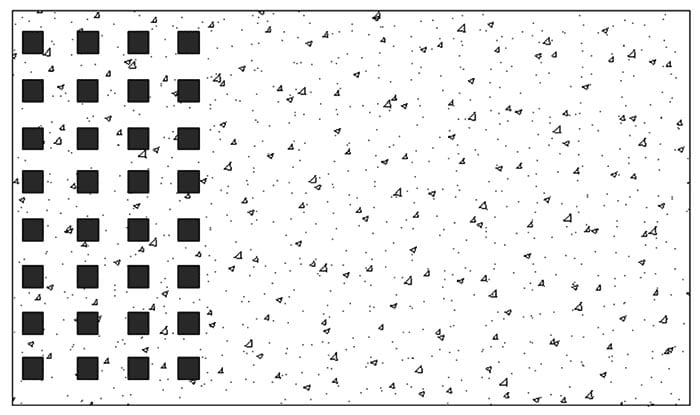

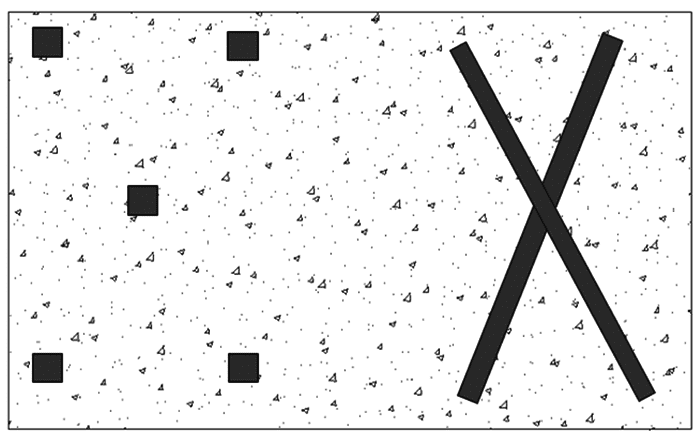

“When applying gypsum board to monolithic concrete, brick or concrete block, the adhesive shall be applied directly to the back of the gypsum board or on the wall in continuous beads not more than 12 in. (300 mm) on centers or daubs spaced not more than 12 in. (300 mm) on centers each way.”

An example of a proper adhesive pattern is shown in the figure below, with some additional application patterns commonly seen below:

It has been frequently observed that the directions of the standard were not followed, resulting in larger air cavities behind the drywall in between the beads of adhesive. This has resulted in a reduction in sound insulation performance of the wall, and in several more extreme cases, reduced the performance to less than the minimum STC requirements of the applicable building code.

Sound Transmission Performance in the Field

When tested in the field, drywall that has been poorly laminated typically exhibits a resonance in the one-third octave bands between 200 Hz and 500 Hz. The resonant frequency and the severity of the reduction in performance is estimated to be proportional to the size of the air cavity between the drywall and the concrete. It should be noted that even if the drywall is laminated to the concrete per the ASTM standard, cavities will still be formed, but the tighter grid translates to an absence of the resonance, and thus the performance is not affected.

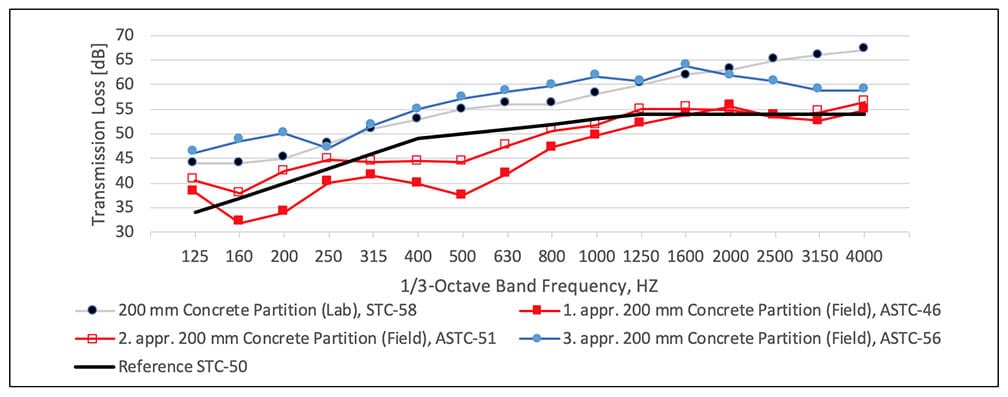

The results of several airborne sound insulation (STC) field tests performed by HGC Engineering are shown in the figure below. The curves on the plot represent the effective transmission loss of several 200 mm thick concrete partitions. The curve with dark blue markers represents laboratory transmission loss data for bare concrete, and the other curves represent field tests of concrete with one layer of gypsum board laminated to both sides. Dips in the performance of the laminated drywall partitions are observed in the frequency bands mentioned above.

It is worth noting that these test results are for poured concrete partitions, but the same concerns exist for other masonry partitions that may include laminated drywall. Although block is a common construction material, it is not often used in a configuration where the degree of airborne sound insulation cannot be tested.

Potential Mitigation Efforts to Increase Acoustical Performance

If poorly laminated drywall is suspected during construction, the most effective solution to the problem would be to remove the drywall and re-apply, with adhesive applied per the standard. However, this is not always practical or cost-effective, especially in buildings in which construction is complete. In one instance, instead of removing the drywall, a contractor applied concrete nails in a grid with a spacing of 150 mm in both directions. This solution reduced the size of the cavities between the concrete and the drywall, effectively damping the resonance. When re-tested, this resulted in a six-point increase in the acoustical performance of the wall (ASTC-46 to ASTC-52).